About Us

History

Formed in 2002, Perftech was an innovator of perforation for shelf-life extension of fresh-cut produce, initially by using hot-needle perforation and subsequently laser perforation. Since then, we have expanded our expertise through multiple complementary perforating technologies. Today we are America’s leading converter specializing in the perforation of flexible substrates.

We moved into a new 60,000-square-foot facility just west of Chicago in 2008. This places us within a three-day shipping radius of nearly every customer. We readily serve converters and packers throughout the nation from our central location.

Our new facility was specially designed for optimal efficiency and hygiene. From the high-gloss paint on the floor to the shatter-proof fixtures on the ceiling, we took great care to ensure our facility would meet the most demanding requirements for material supplied to the food, medical and manufacturing markets.

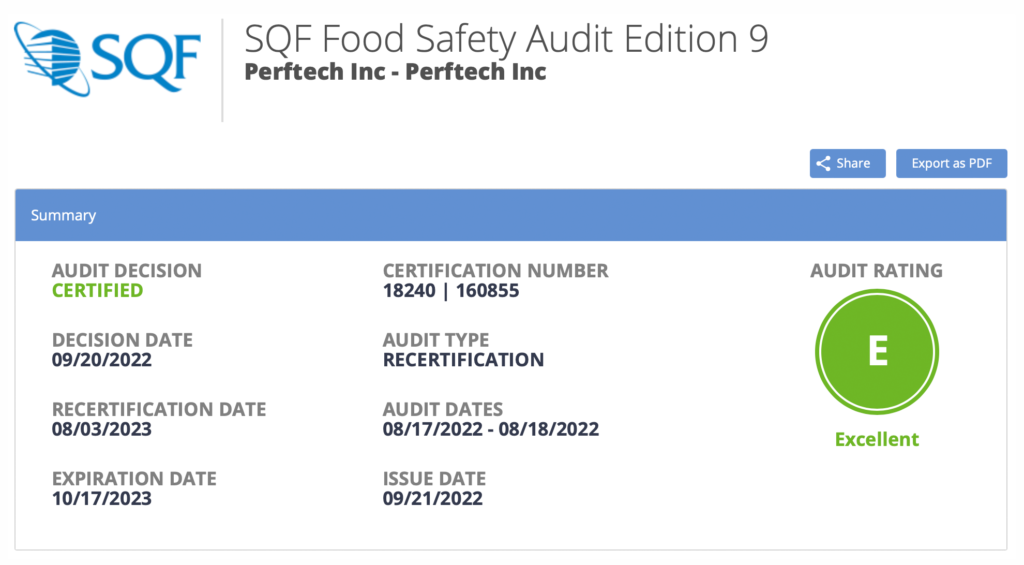

Safe Quality Food (SQF Institute) Certification

Perftech has been granted Safe Quality Food Certification (SQF Code Edition 9: Manufacture of Food Packaging). SQF is a comprehensive HACCP-based food safety and quality management certification system recognized by the Global Food Safety Initiative. It communicates that producers, suppliers, retailers and consumers can be assured of safe, quality food products. SQF certification likewise guarantees greater trust and acceptance among each supplier in the “farm to fork” chain. Perftech has received an Excellent Rating from SQF each year since 2018. We maintain a total commitment to the highest standards for facility hygiene and cleanliness. Our HAACP*-based program ensures that our customers can count on us to safeguard both their material and their reputation. Visit Solutions for Food Applications.

Laboratory Services

Perftech understands that our customers must have confidence in our production. We provide detailed analyses of our perforation work and ensure that all of it can be precisely traced from source roll to finished rolls.

In addition to Six Sigma** statistical analysis of our perforations, we provide routine mechanical testing of customer-supplied material including:

- Microscopic evaluation of perforations

- Tear initiation and propagation

- Coefficient of friction

- Peel/seal strength

- Porosity as measured by airflow

*Hazard Analysis Critical Control Point (HACCP) is the U.S Food and Drug Administration’s management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement and handling, to manufacturing, distribution and consumption of the finished product.

**Six Sigma is a methodology that improves quality by analyzing data with statistics to find the root cause of quality problems and to implement controls. Six Sigma is typically implemented to improve manufacturing.